|

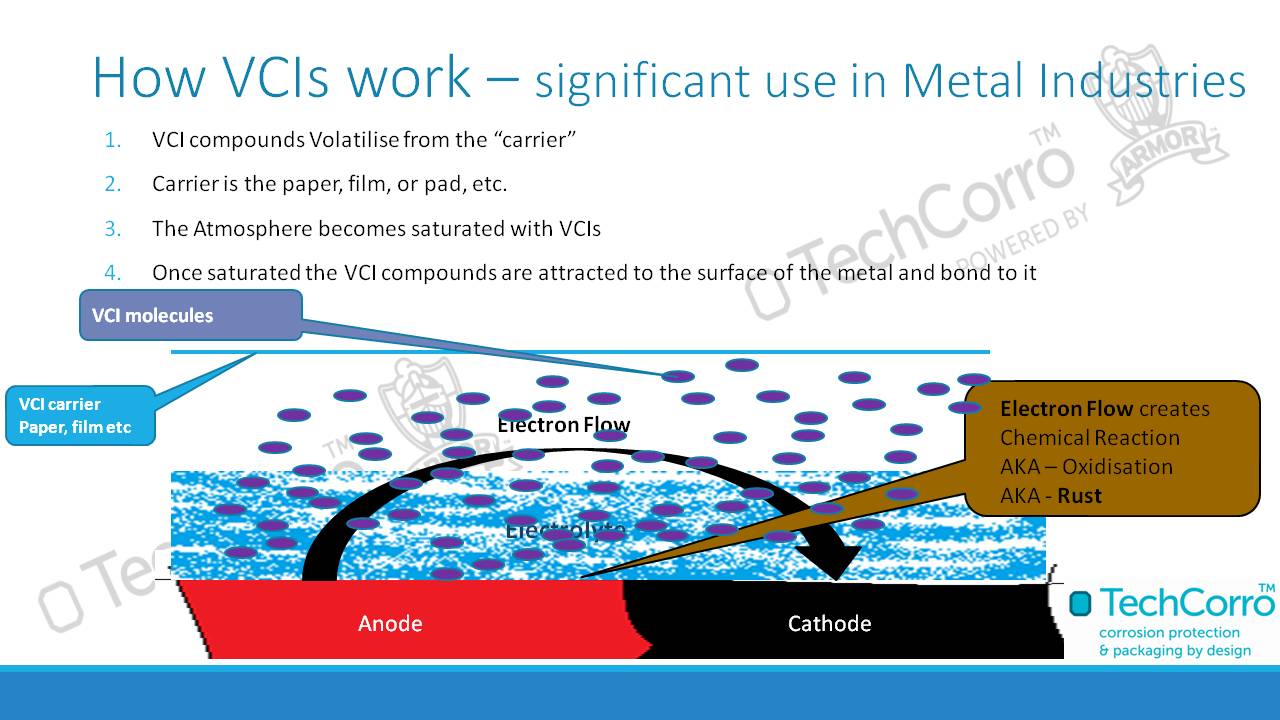

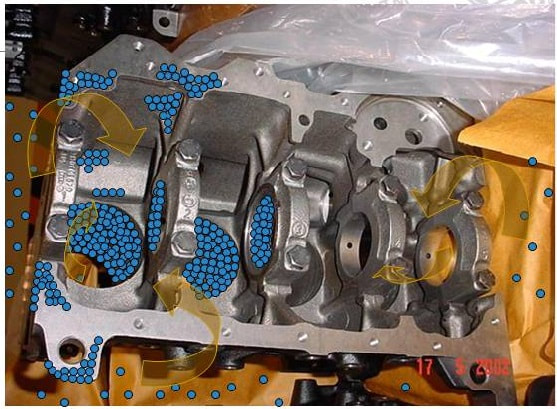

VCI is the generic term for “volatile corrosion inhibitor” also known as “vapour corrosion inhibitor”. We have posted many technical articles on our blog about various types of VCI products and VCI packaging so we thought it would be a good idea to explain exactly what VCIs are and how they work. First off - what IS a Volatile Corrosion Inhibitor? Simply put they are chemical compounds that can reduce the rate of corrosion of ferrous metals like steel and nonferrous metals like copper and alloy. VCIs can be incorporated into different materials and come in various guises depending on the application they are to be used for including films, papers and cardboard and liquid corrosion inhibitors. You will find information and guides to the various types of VCI formulations on our website. VCI compounds comprise several different chemicals but they do NOT clean off rust that has already formed. VCIs are widely used in packaging to protect metal parts during storage and transportation. Other uses include protection of electrical installations, storage tank liners and even the interior of large enclosed spaces.. So how does a Volatile Corrosion Inhibitor work? ● The VCI compounds emit vapour molecules from the carrier material (paper, film, bag etc) ● The atmosphere becomes saturated with VCI. ● The VCI compounds are attracted to the surface of the metal and bonds to it. ● The VCI molecules migrate into hard to reach areas on even the most complex shapes. ● This affects the electro-chemical reaction and forms a protective layer on the metal surfaces, which greatly reduce the possibility of rust and corrosion. How long does a Volatile Corrosion Inhibitor work? The VCI can protect for several years depending on many factors including temperature, storage conditions, type of metal and other packaging. It is therefore important to use the correct VCI product for your particular requirements and Technology Packaging’s team can advise you on your packaging. Where can I find more information?

Help and advice is only a phone call away and will cost your nothing! Our complete range of specialist corrosion preventive packaging uniquely provides us with the ability to give you the best solution for your business. If you have a packaging problem you can Telephone: +44 (0)20 3598 1919 Email: inbox@technologypackaging.com Find further information Compare VCI Products

0 Comments

There exists a wide range of protective packaging products which can be used for protecting ferrous and non-ferrous metals from corrosion during storage and shipping. The most effective of these products use VCI technology - Volatile Corrosion Inhibitors. VCI packaging products are available in different mediums to suit a range of applications including papers, films, foams, bags, cardboard, wire, plastic and liquid. In this article we are focusing on VCI packaging paper. There are several formats of VCI paper packaging such as cut sheets, rolls, plain, creped, bags or with poly coating. These packaging papers protect your metal parts from corrosion when the VCI nanomolecules are attracted to the metal surfaces and form a thin microscopic layer of protection which stops the corrosion cell from forming. The best of these VCI papers also offer protection at a distance which ensures all parts are protected without the need to wrap each individual item even when a piece is not in direct contact with the packaging. Quality VCI packaging paper may also be coated on both sides which can simplify packaging and provide the highest protection levels.  Because of the differences in metallurgical make-up it is important to choose the correct VCI paper formulation for your metal corrosion problem. It is possible to test samples to identify the best VCI paper type to use and we have compatibility charts if required. High quality VCI paper provides an extremely effective solution to corrosion preventative packaging and is clean, safe and easy to use. By using VCI paper to protect your metal products it avoids the mess of using oil and grease based products while protecting metal parts with an easy to apply solution. VCI paper is also fully recyclable unless it is the polythene coated version and can be recycled in normal paper recycling systems. If you would like further information or advice on which VCI paper to use for your packaging solution we will be happy to advise and you can also request samples on our website. In our next post we’ll cover the use and application of VCI films for protective packaging. |

Archives

March 2021

Categories

All

|

Copyright 2018 by Technology Packaging Ltd Privacy Statement & Cookies | Terms Of Use

RSS Feed

RSS Feed