KEY

HC= Highly Corrosive MC= Mildly Corrosive LE= Limited Effect NC= Non-Corrosive

Due to the various chemicals, gases and cleaners within a manufacturing plant, it is imperative to cover metal parts with VCI Packaging as soon after production or processes as possible. Contamination on components is a problem that, depending on the level of cleanliness required, can be extremely serious.

The above chart indicates various gases and their corrosive effects on metals. Whenever possible, it is best to wrap metal parts inside a vapour tight barrier of Volatile Corrosion Inhibitor (VCI) Packaging, to eliminate the possibility of corrosive gases from affecting the component. Technology Packaging provide a full range of best-fit products aimed at making sure customers goods arrive in pristine condition at the lowest cost. Technology Packaging advice is FOC as are the Packaging Audits it can carry out on your or your suppliers packaging. Furthermore, free training can be provided on corrosion and corrosion protection.

To obtain a quote, request a sample or technical support please call

+44 (0) 203 598 19 19 or visit our enquiry page. EXPERT KNOWLEDGE AND QUALITY PRODUCTS ARE NOT EXPENSIVE – THEY’RE INVALUABLE

0 Comments

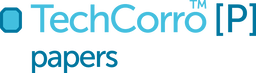

1. Rinse and DRY Packaging metal parts before they are dry Stacking or packing metal parts into boxes after being taken directly out of a cleaning solution without thoroughly drying them will result in rust. When washing or cleaning parts, do not stack or package them until completely dry. Wet parts rust when stacked on top of each other because the fluid acts as an electrolyte and forms a galvanic cell between the two parts. SOLUTION: Make sure metal parts are thoroughly dried before stacking them or packing them into boxes. Placing metal parts in a wire basket allows them to air dry quickly. Vibratory action, forced air, and heat can also dry parts more quickly. Soon after the metal parts are dry, package them in TechCorro™[P] VCI paper or TechCorro™[F] VCI film to prevent corrosion from occurring.  2. Keep it Clean! Dirty cleaning solution causes corrosion Small metal particles, also called swarf, in the metalworking or cleaning solution can end up on metal parts. If not properly washed away, these particles can form a galvanic corrosion cell and corrosion will occur underneath the swarf. SOLUTION: Keep your metalworking fluids and cleaning solutions clean and free of dirt and swarf. Fluids and solutions should be checked on a regular basis and kept free of contaminants that can cause corrosion. 3. Dirty Water Using public/city water for cleaning fluids or water-based rust inhibitors Public/city water can contain high chlorine levels and other chemicals that can cause corrosion. The pH of public/city water can also vary greatly. As we will see in the next most common reason for corrosion, proper pH also plays an important role in preventing rust and corrosion on metal parts. SOLUTION: Switch from public/city water to distilled or deionized water. Additionally, use Dry Coat™ Rust Preventative Spray which is a ready-to-use, water-based rust inhibitor. 4. Adjust the pH! Improper pH level of cleaning solutions Proper pH levels depend on the type of the metal parts. For ferrous parts, a pH level of at least 9.0 should be maintained. For nonferrous metal parts such as copper and alloys like brass and bronze, a pH level of 7.0 - 7.5 should be maintained. SOLUTION: Regularly check and correct pH levels of all cleaning solutions. Adjust pH levels according to usage guidelines.  5. Never Play With Fire! Storage of metal parts near manufacturing areas Metal parts stored close to manufacturing areas, specifically heat-treating and grinding processes, can become contaminated which leads to corrosion. SOLUTION: Cover all metal parts with TechCorro™[P] VCI paper or TechCorro™[F] VCI film to protect them. 6. Keep Your Cool! Failure to maintain the proper temperature in manufacturing and shipping areas For every 10 degree Celsius increase in temperature, corrosion rates can double. Fluctuations in temperatures cause metal pores to open and can also cause condensation to form on parts. Condensation becomes an electrolyte, allowing corrosion to occur. High humidity can cause electrolytes to form on the surface of metal parts enabling the corrosion cell to form and allowing corrosion to propagate. When packaging parts in high humidity that kind of atmosphere is being locked into the package. SOLUTION: Maintain lower temperatures and lower humidity levels by installing climate controls, air conditioning, and/or dehumidifiers.  7. Cover Up! Leaving metal parts uncovered and unprotected Leaving parts uncovered while sitting in the plant, waiting for secondary operations, in queue for additional machining, drilling and tapping, waiting to be packaged, etc. makes parts susceptible to rust and corrosion. Parts left uncovered in the plant are susceptive to forklift exhaust. Chlorides, sulfides, and oxides from the exhaust contribute to the corrosion of metal parts. SOLUTION: Cover all metal parts with TechCorro™[P] VCI paper or TechCorro™[F] VCI film, protecting them from oxygen and contaminants that are in the plant atmosphere.  8. Caught Red-Handed! Employees handling metal parts with bare hands Fingerprints and perspiration are one of the biggest contributors to corrosion. Acids, oils, and contaminants on human hands can cause and accelerate corrosion. SOLUTION: All employees who handle metal parts including production workers, inspectors, and packaging personnel should always wear gloves when handling parts.  9. Not So Eco-Friendly Direct contact of metal parts with corrugated cardboard, wood, or paper All forestry products (wood, paper, or corrugated board) contain moisture, acids, and chlorides that cause corrosion. Direct contact with these materials causes “contact corrosion” meaning parts will rust in the areas of direct contact that is made with these products. This often causes sporadic rust having some parts in a particular shipment with rust and others without. Under certain conditions some glues used in corrugated cardboard may give off corrosive gasses. SOLUTION: Line boxes, crates, etc. with TechCorro™[P] VCI paper or TechCorro™[F] VCI film. This creates an effective barrier between metal parts and the wood sourced products that cause rust.  10. Oil Doesn’t Mix Use of rust preventative oils instead of VCI packaging R.P. Oils are the traditional method of preventing rust and corrosion. However, R.P. Oils are messy, labour intensive, and bad for the environment. R.P. Oils are less effective than VCI products when it comes to preventing rust. SOLUTION: The obvious solution to this mistake is to switch from R.P. Oils to TechCorro™[P] VCI paper, TechCorro™[F] VCI film, or Dry Coat which is a waterbased, rust inhibitor liquid. We have successfully helped hundreds of companies switch to TechCorro™ products from R.P. Oils producing great results!  11. Know the Product Improper use of VCI products due to lack of knowledge Another common reason for corrosion on metal is using poor quality VCI products. Too high a vapour pressure will cause the inhibitor to be released to such an extent that a protective concentration cannot be maintained. On the other hand, a low vapour pressure inhibitor is not used up as quickly and can assure more durable protection, but more time is needed for a protective vapour concentration. Proper selection of volatile compounds enables controlled and dependable volatilisation. SOLUTION: Always follow TechCorro™ usage guidelines when using TechCorro™ products. Consult with an expert to design a VCI system for your specific application and help you implement the usage of TechCorro™ products properly. Technology Packaging team members are always happy to help.  12. Can’t Get Enough VCI! Not using enough VCI product The internal space needs to be saturated with VCI vapour before the VCI can condensate on the metal surface. If the amount of VCI is not sufficient, a protective concentration may never be reached. More than 1000 types of VCI compounds are known, but only a fraction of them are efficient, cost effective, and environmentally friendly. SOLUTION: As a general rule, use 1 m² (10 ft²) of TechCorro™[F] VCI film for every 1 - 2.5 m² (10 - 25 ft²) of metal surface. Use at least 4-6 m² of TechCorro™[P] VCI paper for every 1m3 of void space.  13. Do the Homework Lack of knowledge and training Technology Packaging cannot control variable conditions such as temperature, humidity, airflow, end-user production methods, surface area of metal to be protected, customer employee training, and other factors that are beyond our control. It is impossible to guarantee any shelf life in this regard. However, Technology Packaging does guarantee the amount of VCI that is impregnated into the packaging for two years. SOLUTION: Make sure to follow TechCorro™ usage guidelines and train all employees accordingly. Technology Packaging provide bespoke packaging and corrosion preventive training to its customers.  14. Protection Radius Improper placement of VCI products The corrosion protection radius depends on the vapour pressure of the VCI used in the master-batch formulation. Ingredients with higher vapour pressure can reach farther areas and are usually called Vapour Phase Protectors. Ingredients with lower vapour pressure only reach areas in close proximity and are usually called Contact Phase Protectors. SOLUTION: VCI vapours from TechCorro™[P] VCI paper can diffuse into the air up to 30cms. Under normal circumstances don’t place metal parts beyond 30cms away from the closest VCI source unles you check with Technology Packaging’s team.  15. Condensation! Moisture: the main corrosion promoter. Moisture accelerates corrosion. Moisture can cause normal temperature variations to be accentuated inside of a package making air move upwards, like in a chimney. As air either heats or cools, it flows up and down inside the package causing temperature variations and repeated evaporation and condensation. Condensation and evaporation cycles will repeatedly bring contaminates in contact with the metal surface as well as provide thermal conductivity promoting temperature gradients and electrical potential differences on the metal surface.  SOLUTION: Stuff TechCorro™[P] VCI paper into the packaging to prevent the chimney effect and block any air flow. Another solution is the use of TechCorro™ Desiccant to absorb moisture inside of the package.  There exists a wide range of protective packaging products which can be used for protecting ferrous and non-ferrous metals from corrosion during storage and shipping. The most effective of these products use VCI technology - Volatile Corrosion Inhibitors. VCI packaging products are available in different mediums to suit a range of applications including papers, films, foams, bags, cardboard, wire, plastic and liquid. In this article we are focusing on VCI packaging paper. There are several formats of VCI paper packaging such as cut sheets, rolls, plain, creped, bags or with poly coating. These packaging papers protect your metal parts from corrosion when the VCI nanomolecules are attracted to the metal surfaces and form a thin microscopic layer of protection which stops the corrosion cell from forming. The best of these VCI papers also offer protection at a distance which ensures all parts are protected without the need to wrap each individual item even when a piece is not in direct contact with the packaging. Quality VCI packaging paper may also be coated on both sides which can simplify packaging and provide the highest protection levels.  Because of the differences in metallurgical make-up it is important to choose the correct VCI paper formulation for your metal corrosion problem. It is possible to test samples to identify the best VCI paper type to use and we have compatibility charts if required. High quality VCI paper provides an extremely effective solution to corrosion preventative packaging and is clean, safe and easy to use. By using VCI paper to protect your metal products it avoids the mess of using oil and grease based products while protecting metal parts with an easy to apply solution. VCI paper is also fully recyclable unless it is the polythene coated version and can be recycled in normal paper recycling systems. If you would like further information or advice on which VCI paper to use for your packaging solution we will be happy to advise and you can also request samples on our website. In our next post we’ll cover the use and application of VCI films for protective packaging.  Corrugated board and made-up cartons impregnated with specially formulated chemical compounds will provide corrosion protection for ferrous and non-ferrous metals. This state-of-the-art corrosion preventive packaging is saturated with VCI chemical to provide a fast-acting and long-lasting protection and is available both as one-sided and two-sided material. You can find detailed information on the metals protected and any compatibility issues on our compatibility charts. How VCI Cartonboard Provides Protection VCIs emit small amounts of harmless active corrosion inhibitors. They are attracted to the charged surface of the metal. The flow of electrons in the metal and the flow of ions in the electrolyte surface is unable to operate and corrosion is halted. The length of protection depends on many factors and Technology Packaging staff are available to answer specific questions on corrosion protection or to provide detailed, objective proposals on suitable methods. This is true whether the problem relates to new projects or existing problematic transit and/or storage systems. Using VCI Carton Material This material can be ‘layered’ between components because VCI works at a distance as well as in contact with the metal. The corrugated material provides cushioning against mechanical damage. Technology Packaging can supply information on the quantity of VCI material required for a pack. VCI Corrugated paper material can be supplies sheets, wide and narrow rolls and die-cut formats. Advice for Handling VCI Cartonboard Ideally the material should be kept cool, dry and protected from direct sunlight. It is preferable to keep it in its original wrapping when possible. If kept in these conditions the material will be effective for a minimum of three years. Skilled technicians are constantly reviewing & developing new products that are often customer led. If you would like to know more about protecting your valuable manufactured goods during storage and transit please get in touch. Protective Packaging SolutionsDid you know your Corrugated Cardboard packaging could be causing corrosion? When using corrugated cardboard in packaging, it is important that the cardboard is specially treated or the acidity that is oftenn present in the fibres can transfer to the metal part(s) causing corrosion. Cardboard sheets are often used to separate one row of parts from another in a package. If the cardboard is not treated, the cardboard will absorb moisture in storage and transit and will induce corrosion on the surface of the parts that is in contact with the cardboard.  In the manufacturing process of corrugated cardboard, the pulp is dissolved by nitric acid. This acid has to be neutralised using several rinsing steps. To save money, some manufacturers shorten these rinsing steps and consequently there is acidic residue that remains in the pulp used to make the cardboard. Additionally, some of the glues used can add to the corrosion hazard. During transportation, especially during night hours when the temperature goes down and relative humidity goes up, porous packaging like corrugated cardboard absorbs moisture and it activates any acidic residue left behind. If the cardboard is in direct contact with the metal parts, it can easily lead to corrosion by providing an acidic electrolyte as demonstrated in the photo to the right.  As a solution, the surface of metal parts should never be allowed to touch corrugated cardboard. A sheet of VCI film or paper (such as TechCorro™[F] VCI film or TechCorro™[P] VCI paper) should be placed between the cardboard surface and the metal part (as shown in the photo below). A sheet of VCI film should also be placed on the top row of parts to prevent the cardboard from touching the row of parts immediately below it. Another approach would be to insert the cardboard sheet into a flat bag made of VCI film thereby covering both sides of the cardboard sheet. Assessing the shipping and packaging conditions and other variables that can influence corrosion formation allows for the design and use of protective packaging solutions that will preserve and protect. While moisture cannot be completely removed from the packaging, porous packaging materials reduce relative humidity and condensation (as long as they are not acidic porous packaging which can actually increase corrosion as described above). TechCorro™ VCI Nanotechnology, found in Technology Packaging’s product line, responds and adjusts to temperature and humidity fluctuations, increasing and decreasing as needed. Free Advice On Corrosion Preventative Packaging SolutionsFor more information on how corrosion preventative packaging can help your business please call us on 020 3598 1919 or email sales@technologypackaging.com

The Advantages of Proper Packaging

Correct packaging can help prevent damage during storage and transportation. The use of a dedicated ergonomic packing station will streamline production and will help to protect products from different risks. Products can be packaged in a way that the quality of product is not at risk from corrosion or damaged in transit. Packing benches can include simple paper and film cutting to a complete system for any sized operation. Key Benefits of Packing Benches and Packaging Workstations

TechCorro™[EQ] Packaging Benches and Installations We offer a complete range of packing benches that are modern, multi functional, ergonomic and expandable. Our range of ergonomic Work and Packaging benches also offer a comprehensive range of fittings to provide the best-fit equipment for a wide range of industries. If you require just a single packing bench, a packaging bench with cutters, scale platforms or a complete system for a new factory our extensive range of packing benches and components can provide what you require. |

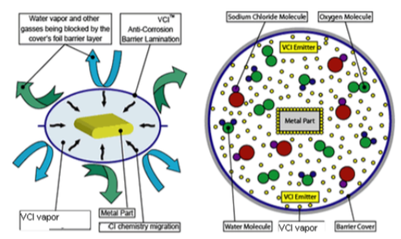

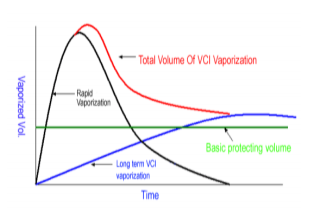

Archives

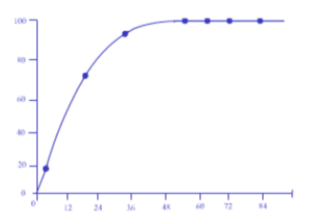

March 2021

Categories

All

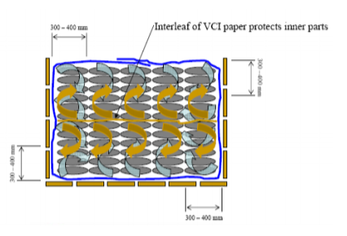

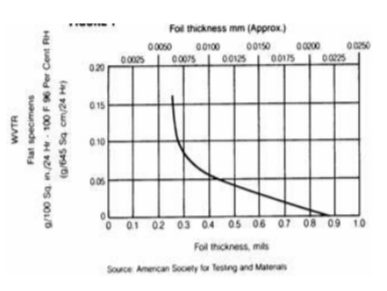

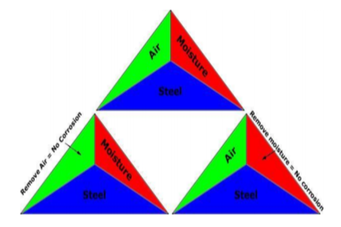

|

Copyright 2018 by Technology Packaging Ltd Privacy Statement & Cookies | Terms Of Use

RSS Feed

RSS Feed