|

The choice between the use of VCI paper or VCI poly (film) can be a difficult one. It can be determined by the answers to three questions: 1. What is the application? 2. Where is the product being shipped and stored? 3. How demanding is the shipment?  What is the application? Is the metal object to be protected a single part or multiple parts? Is the metal object in a returnable container or a corrugated one-way box? Is the object a large piece of machinery or a small gear? How long from when packaging is completed, will it be shipped? What are the process conditions? Typically, VCI film is easier and more cost-effective to produce into bags compared to paper. When multiple parts are in need of protection, the use of a poly bag is a simple and easy alternative to wrapping them in VCI paper. In the case of returnable containers, a VCI poly bag is often used to enclose the entire container and depending upon the returnable trays or layers, paper or film may be used. If the item is a large piece of equipment, it is not feasible to wrap the entire piece in paper because the paper can become wet and break down. In these situations, a combination of both is recommended -- use VCI paper on the inside for sensitive areas and VCI film on the outside to enclose the unit and provide barrier properties.  Where is the product being shipped and stored? Is the metal item being shipped from Nottingham to Newcastle or from Manchester to Michigan? Is the item going to be stored for three months inside a controlled warehouse or four years? As a general rule, if something is going to be exported, the items should be protected in an enclosed bag. A VCI poly bag will provide moisture and oxygen protection as well as the VCI corrosion inhibitor. Using a non-VCI bag and VCI paper is another alternative. Making the choice will be based on cost, on the level of protection required, on the ease of the packaging process as well as other factors. That said, if a part is being packaged in a humid environment and then shipped, a combination of VCI paper and VCI poly may be necessary – see ‘Some facts..’ below. Additional VCI paper would be used inside the package with VCI poly encompassing the outside of the entire package to provide a moisture and oxygen barrier.  How demanding is the shipment? Has there been an ongoing rust problem? Are the metals highly sensitive to corrosion? In the case of ongoing rust problems, Technology Packaging typically leads with VCI paper as the first line of defence. Paper is used as a “carrier” of the VCI chemical because paper is more porous than film. Paper allows the VCI to leave it more rapidly providing quicker protection to the metal surface. In the case of flash-rust concerns for example, VCI paper is a better option. Some facts about VCI polythene films: • Offers the combined benefit of barrier materials with anti-corrosion properties. • Ideal for large bulk items in bins (nuts, bolts, etc.) such as a bin liner bag. • Great for large equipment that cannot be wrapped in paper. • Film, especially high-density polyethylene, is conformable and may be a better fit as a tray liner for trays with cavities. • Film has more flexibility to be converted into more convenient packaging methods such as zipper bags, tubing and elastic bonnets. Some facts about VCI paper: • Provides a quicker vapour corrosion inhibitor. Paper as a carrier is more porous and allows the VCI chemical to leave the paper faster than film and fill the enclosed air-space more quickly than VCI film. • TechCorro™[P] papers are impregnated with VCI which allows for easy interleaving between layers of parts (top and bottom). • VCI papers are better at protecting highly sensitive parts that allow for a full wrap. • VCI papers provide some secondary absorption properties due to the fact that the paper as a carrier is porous. • VCI paper works at a greater distance than VCI film Get advice:

Technology Packaging experienced staff are trained in asking the right questions and providing sound, objective and free reports allowing for the best-fit solutions. To obtain a quote, request a sample or technical support please call +44 (0) 203 598 19 19 or visit our enquiry page. EXPERT KNOWLEDGE AND QUALITY PRODUCTS ARE NOT EXPENSIVE – THEY’RE INVALUABLE

0 Comments

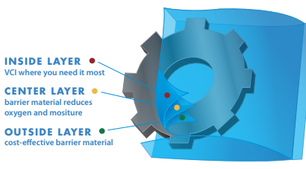

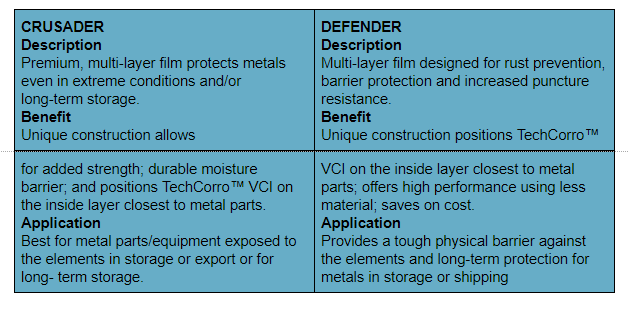

Tough, Durable Cost-Effective VCI Film What is VCI? VCI is an acronym for Volatile Corrosion Inhibitor. When you combine VCI compounds with ferrous or non-ferrous metal in an enclosed space like a bag, container, tool box, or storage bin, something magical happens. VCI molecules are released and they are attracted to the surface of the metal just like a magnet. Even more amazing, the VCI molecules attach themselves to the surface of the metal and they form a thin, protective shield. Just imagine, it is like covering metal or metal parts with a warm, cozy blanket that keeps the rust away. Defender and Crusader VCI Films Technology Packaging stock a comprehensive line of Volatile Corrosion Inhibitor (VCI) films. These TechCorro™VCI films are your first choice for those looking for a film that is strong, puncture resistant and reusable. The VCI film is made from high-tech resins and cutting-edge extrusion technology and co-extruded with three, unique layers. This three-layer construction (most VCI films are single layer) positions VCI on the inside, closest to the metal part, and offers a stronger, more durable moisture barrier ideal for extreme conditions or long-term storage. Defender VCI film is 25% thinner than Crusader and results in cost savings of up to 15% while exceeding the material properties of thicker film. To find out which product will be the best solution for your requirements please submit a support request or give us a call. Defender VCI Bags The Defender is a co-extruded VCI poly bag that provides a cost-effective alternative to standard mono-extruded films. Economical and tough it makes use of three layers of film to prevent corrosion and provide additional barrier protection while increasing durability and puncture resistance. Crusader VCI Bags The Crusader is also a co-extruded VCI poly bag that provides a higher protection level than standard mono-extruded films and even Defender films. They are tough and use three layers of film to prevent corrosion and provide much improved barrier protection while increasing durability and puncture resistance. These Defender & Crusader VCI bags provide outstanding corrosion inhibiting performance. VCI Film Applications

Our range of VCI films were developed for the most demanding corrosion-inhibiting applications and are designed to prevent corrosion, provide additional barrier protection, and to increase durability and puncture resistance at an economical price. Defender and Crusader VCI films provide 50% more barrier protection than comparable mono-extruded film. This makes them ideal for metal parts needing corrosion prevention and containment or providing barrier properties in shipping or storage, bin liners or for long-term storage. Corrosion Prevention Technology With 20 years in business, Technology Packaging offers a full line-up of corrosion inhibiting VCI products that are clean, safe, easy to use and extremely effective. We provide innovative protective packaging products and best in class corrosion protection solutions with our range of VCI papers and films, VCI emitters, desiccants and rust prevention and remover liquids. Our protective packaging materials are clean, safe and provide an easy replacement for other common rust prevention methods like grease, oils or other messy protective coatings. If you would like to discuss your requirements, or request a sample or request technical support we will be happy to help. You can also request a quote for a specific project and find additional information about all our products and services at www.technologypackaging.com or just give us a call on +44 (0)20 3598 1919 |

Archives

March 2021

Categories

All

|

Copyright 2018 by Technology Packaging Ltd Privacy Statement & Cookies | Terms Of Use

RSS Feed

RSS Feed