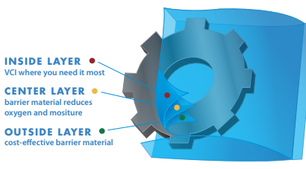

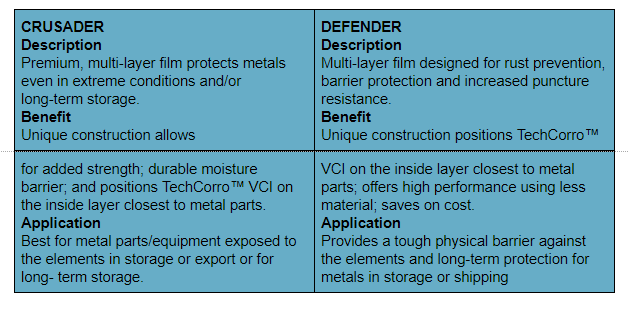

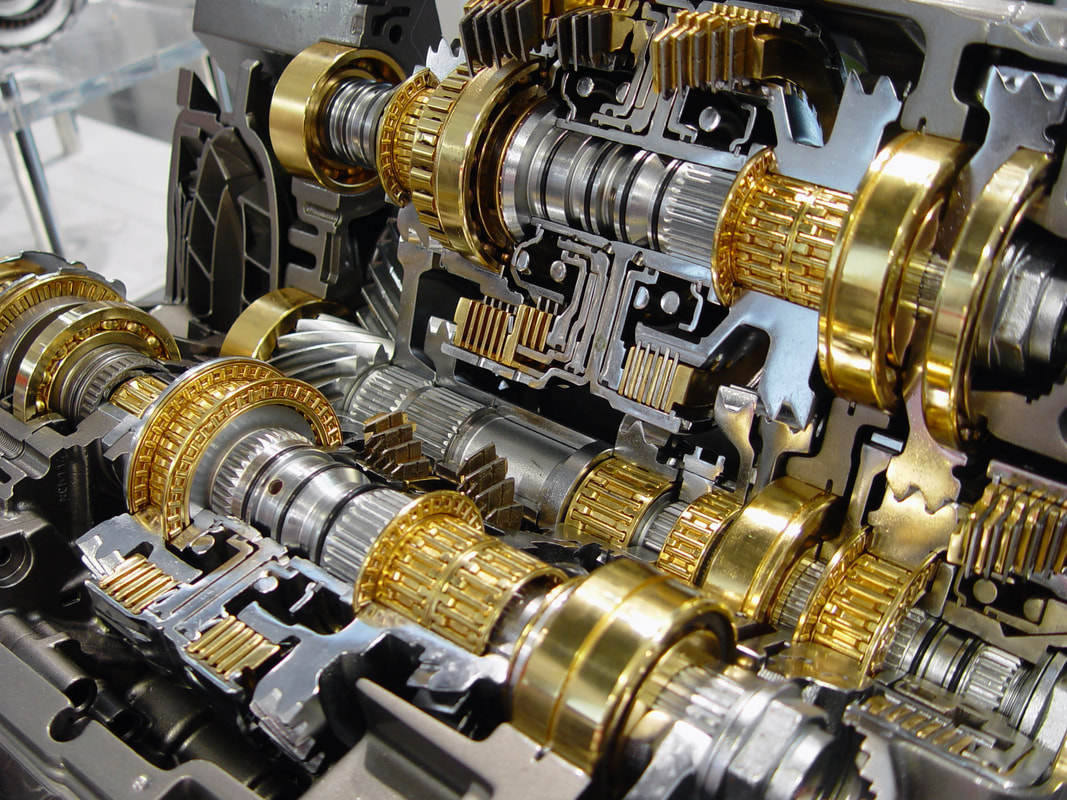

Tough, Durable Cost-Effective VCI Film What is VCI? VCI is an acronym for Volatile Corrosion Inhibitor. When you combine VCI compounds with ferrous or non-ferrous metal in an enclosed space like a bag, container, tool box, or storage bin, something magical happens. VCI molecules are released and they are attracted to the surface of the metal just like a magnet. Even more amazing, the VCI molecules attach themselves to the surface of the metal and they form a thin, protective shield. Just imagine, it is like covering metal or metal parts with a warm, cozy blanket that keeps the rust away. Defender and Crusader VCI Films Technology Packaging stock a comprehensive line of Volatile Corrosion Inhibitor (VCI) films. These TechCorro™VCI films are your first choice for those looking for a film that is strong, puncture resistant and reusable. The VCI film is made from high-tech resins and cutting-edge extrusion technology and co-extruded with three, unique layers. This three-layer construction (most VCI films are single layer) positions VCI on the inside, closest to the metal part, and offers a stronger, more durable moisture barrier ideal for extreme conditions or long-term storage. Defender VCI film is 25% thinner than Crusader and results in cost savings of up to 15% while exceeding the material properties of thicker film. To find out which product will be the best solution for your requirements please submit a support request or give us a call. Defender VCI Bags The Defender is a co-extruded VCI poly bag that provides a cost-effective alternative to standard mono-extruded films. Economical and tough it makes use of three layers of film to prevent corrosion and provide additional barrier protection while increasing durability and puncture resistance. Crusader VCI Bags The Crusader is also a co-extruded VCI poly bag that provides a higher protection level than standard mono-extruded films and even Defender films. They are tough and use three layers of film to prevent corrosion and provide much improved barrier protection while increasing durability and puncture resistance. These Defender & Crusader VCI bags provide outstanding corrosion inhibiting performance. VCI Film Applications

Our range of VCI films were developed for the most demanding corrosion-inhibiting applications and are designed to prevent corrosion, provide additional barrier protection, and to increase durability and puncture resistance at an economical price. Defender and Crusader VCI films provide 50% more barrier protection than comparable mono-extruded film. This makes them ideal for metal parts needing corrosion prevention and containment or providing barrier properties in shipping or storage, bin liners or for long-term storage. Corrosion Prevention Technology With 20 years in business, Technology Packaging offers a full line-up of corrosion inhibiting VCI products that are clean, safe, easy to use and extremely effective. We provide innovative protective packaging products and best in class corrosion protection solutions with our range of VCI papers and films, VCI emitters, desiccants and rust prevention and remover liquids. Our protective packaging materials are clean, safe and provide an easy replacement for other common rust prevention methods like grease, oils or other messy protective coatings. If you would like to discuss your requirements, or request a sample or request technical support we will be happy to help. You can also request a quote for a specific project and find additional information about all our products and services at www.technologypackaging.com or just give us a call on +44 (0)20 3598 1919

0 Comments

The Advantages of Proper Packaging

Correct packaging can help prevent damage during storage and transportation. The use of a dedicated ergonomic packing station will streamline production and will help to protect products from different risks. Products can be packaged in a way that the quality of product is not at risk from corrosion or damaged in transit. Packing benches can include simple paper and film cutting to a complete system for any sized operation. Key Benefits of Packing Benches and Packaging Workstations

TechCorro™[EQ] Packaging Benches and Installations We offer a complete range of packing benches that are modern, multi functional, ergonomic and expandable. Our range of ergonomic Work and Packaging benches also offer a comprehensive range of fittings to provide the best-fit equipment for a wide range of industries. If you require just a single packing bench, a packaging bench with cutters, scale platforms or a complete system for a new factory our extensive range of packing benches and components can provide what you require. If you are looking for a safe and easy method of preventing rust attacking your valuable goods and machinery we have the solutions you need.

There are a number of liquid products on the market designed to protect metals from corrosion but deciding on the correct liquid to use can be confusing and we’re here to help. Liquid Corrosion Inhibitors (also known as LCIs) are safe and easy to use for the prevention of corrosion. In addition to their use during production, LCIs are often used during packaging and may be the only rust preventative that is needed. There are today liquids available that do not contain volatile compounds and are therefore inherently safer and ecologically safe. Our range of TechCorro™[FL] Liquid Corrosion Inhibitors include:

To choose the best product for your own application the following should be considered:

You should also consider whether you wish to use environmentally friendly products that are VOC (volatile organic content) free. Technology Packaging offers a complete range of rust preventive liquids which are designed to prevent rust on bare metals and unpainted metal parts. Exposed metal can be protected during manufacture, in storage and during transit. Liquid corrosion inhibitors can be applied by brush or sprayed into difficult to reach areas using standard equipment and are suitable for indoor or outdoor protection. Typical Applications for Rust Preventative Liquids

It is important to use a corrosion prevention product that is suitable for your particular requirements. Whether your task is to protect goods during manufacturing, short or long-term storage or shipping we are able to provide technical advice and support for your application. Our range of easy and safe rust prevention liquids means we are able to supply the best-fit product for your task. When production is shutdown for changeovers or preventative maintenance the use of VCI protective Packaging (volatile corrosion inhibitor) products will greatly assist a safe and easy rust free downtime. We recommend that parts are completely wrapped or enclosed in airtight packaging for the most effective results and longest protection time. We have listed five stages in a manufacturing environment that will help to enhance the effectiveness of VCI packaging and reduce corrosion during shutdowns.

TechCorro™ Products Choosing the right VCI products will ensure that your products remain safe during production shutdowns. We have made available a number of technical documents that can be downloaded which can help you choose the right products. You can also request further information or assistance on your particular corrosion problem by contacting us directly. Technology Packaging is a company that produces and supplies a range of VCI products and has a great deal of expertise and experience in corrosion protection and rust prevention in different industries. Our advice and experience will save you time and money, as we will always objectively advise on the best VCI products and solutions to use during manufacturing shutdowns. Please get in touch for a tailored rust protection solution or request a quote for specific corrosion protection products.

Temporary corrosion protection in this context does not mean ‘for a short time’. Many pieces of equipment and components need to be protected from the point of manufacture to the time when they are to be used. This period can be anything from 10 minutes to 10 years. Temporary Corrosion Protection

Permanent corrosion protection is something that is applied and cannot be easily removed. Paint is a good example of a permanent corrosion preventive. Temporary refers to the fact that the corrosion protection system is something that can be easily removed. Technology Packaging produces and supplies a specialised range of packaging materials designed to stop corrosion of metal products during transit and storage. Objectivity is vital to make sure the best-fit products are used so Technology Packaging are passionate about having the widest range possible.

Products designed for the Auto-Wrapping of coils and sheets VCI films: Mono, Co-ex, Hi-Impact, Stretch, Shrink, Flow-wrap, Laminated using many different polymer types and specially developed and constructed technical products. Most of these can be supplied without VCI where other adequate corrosion protection is used or if the product does not require it, e.g. Painted metals or aluminium. All of innovative temporary corrosion prevention products can be printed with company names and/or logo to endorse a company’s message or adhere to marketing requirements. When we analyse your packaging and corrosion prevention requirements we will often be able to introduce an improved system or product that will improve effectiveness and reduce costs of packaging during storage and transportation. Technology Packaging with it’s TechCorro™ range of Temporary Corrosion Protection (TCP) products provides corrosion protection for components and items that are in transit or storage for anything from 10 minutes to 10 years or longer. The word ‘Temporary’ in this case simply means that the systems used are not ‘permanent’ such as paint and can easily be removed. Sometimes a form of Permanent Corrosion Protection (PCP) is required and below we explain a few possibilities.

Whether on cars, tools, or equipment, rust is something nobody wants to deal with. It’s messy, it breaks equipment down over time and, too often, it means hours scrubbing with a wire brush. The best way to deal with rust is to not let it get a foothold in the first place. Knowing how to stop rust can save you a lot of time and money in ruined equipment. TechCorro™ products provide many industries with TCP items to ensure that when the component arrives at its destination it is in pristine condition and ready to be used without any time wasting. Read on to see what you can do for some more permanent systems. Permanent Corrosion Protection Polymer Topcoat One great option for protecting your materials from rust is to use a polymer topcoat. These sealants act as a shield between the metal and the oxidizing elements in the air. They are incredibly durable and can last as long as the material would anyhow. Some polymer topcoats can withstand as much as 280 degrees Centigrade. It’s true that these treatments can be expensive, a few hundred pounds or more to coat your materials but compared to the cost of replacing rusted parts, this option well pay for itself. Anodic Protection You can also use anodic protection to keep your components from rusting. This is a similar concept to polymer topcoats in that they rely on a protective layer being laid over your metal materials. In this case, the coating is other metals, not polymers. Metals like aluminium and tin don’t oxidize as fast when exposed to air and water and so won’t rust. You can coat your materials in one of these metals and never have to worry about rust again. This can give you the sturdiness of steel without having to deal with cleaning up rust all the time. Corrosion-Resistant Metals Depending on your application, you may be able to use corrosion-resistant materials. As we mentioned, tin and aluminium don’t rust, and aluminium has its own advantages. In the case of aluminium in particular, it’s much lighter than many other metals, which can make it more fuel-efficient and easier to move. Zinc and stainless steel are other options for corrosion-resistant materials to go for instead. Your choice will depend largely on the requirements for your application. Learn How to Stop Rust No one enjoys fighting rust, and in some cases, it can get dangerous but knowing how to stop rust can save you a lot of time scrubbing down rusty parts and money buying new ones. Take a look at what your application requires and find the rust prevention technique that works best for you. If you’d like to learn more about corrosion protection, check out the rest of our site. We can help you improve your corrosion protection and protective packaging technology to save your business as much money as possible. Check out our VCI Packaging Products for Corrosion Protection and other TechCorro™ items such as Barrier Foil Laminates to find the right temporary corrosion protection for you. |

Archives

March 2021

Categories

All

|

Copyright 2018 by Technology Packaging Ltd Privacy Statement & Cookies | Terms Of Use

RSS Feed

RSS Feed